Innovation for the future, safety in every step.

Meet our team of talented professionals based in Pomerania in Poland.

Every day we invent, design and code smart devices that transform production,

safeguard operations and bring tomorrow’s opportunities into your factory today.

Tag for Vehicles

Mounted on movable assets as Vehicle (e.g., forklifts) or on fixed infrastructure elements as Fixed (e.g., gates, racks, machines).

The Fixed mode transforms passive infrastructure into an active element of the safety ecosystem, allowing vehicles to react to the proximity of specific locations,

and not just other moving objects.

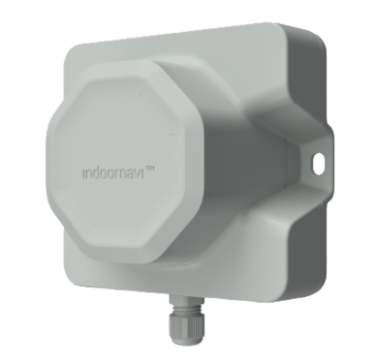

Anchor

It serves as an active creator of intelligent zones (Area). Anchors, mounted permanently (e.g., under the ceiling), define the boundaries of virtual areas.

Four Anchors designate one zone (Area), whereby zones can overlap, and a single Anchor can be part of up to four different zones, which ensures tremendous flexibility and scalability of the system.

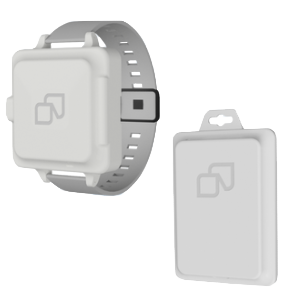

Tag for pedestrians

Available in two forms: as a card on a lanyard (Personal Card) or a wristband (Personal Band).

These Tags have a built-in buzzer and vibrations, which are used to send notifications and alerts directly to the employee, e.g., about an approaching vehicle.

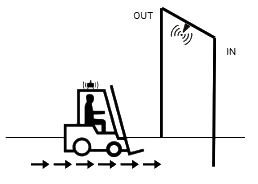

Virtual Gate

As a complement to the zone-based system, IndoorNavi offers the Gates subsystem, operating using infrared (IR) technology.

It is used for precise control of entry and exit in narrow passages, such as gates or corridors.

It consists of three elements :

Gate Transmitter – Transmitter mounted on the infrastructure. It generates appropriate signals defining two zones: IN and OUT.

Gate Receiver – Receiver mounted on the vehicle. It receives the code from the Gate End and, based on it, activates or releases vehicle deceleration.

Gate End – Emitter sending an infrared signal.

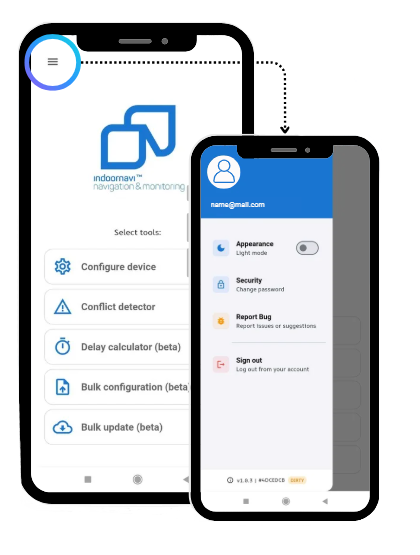

Management

The system analyzes data and reacts immediately. Users receive notifications (e.g., vibrations on a Personal Tag), and the system activates external devices (e.g., decelerating a forklift to avoid a collision.

Administrators have access to current and historical data. They can analyze the movement paths of objects and identify problems, which allows for continuous process improvement and optimization strategies.

Historical data allows for detailed process analysis.